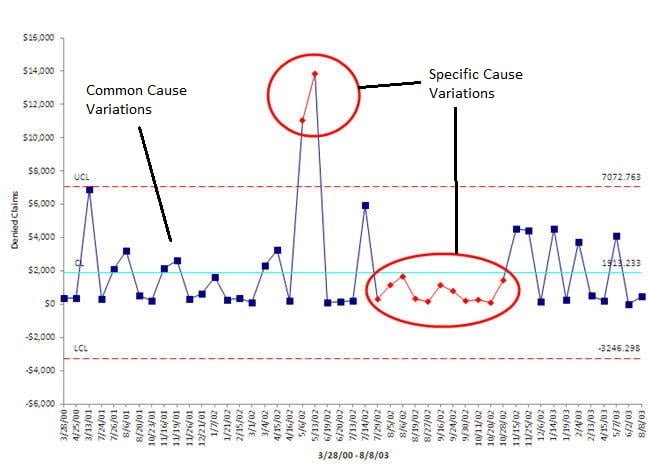

Common Cause vs. Special Cause Variations in Control Chart

Project Quality Management – Control Chart – Common Cause vs. Special Cause Variations

Maintaining health of a process for continuously delivering quality product using control chart.

Whatsoever we are producing we see that our outcomes are not exactly identical. If we are producing any part of an automobile or a food product or anything else, we observe some variations. If the variation is very small, we may ignore it but variation still exist. These variations could be because of human errors or defect in a machine or error within acceptable precision in a machine, in the environment, changing temperature etc. Some of them may be acceptable to us as they are within our control limits but some may not be acceptable as they are categorized as defects.This concept is used in Control Chart to maintain the health of a process so that process always deliver quality product without any defect. It is also used in Six Sigma.

There are basically two types of causes that results into these variations. Common cause and specific cause. These terms are defined by Walter A. Shewhart and W. Edwards Deming.

Common cause variations is where combination of factors or no visible factor affected the process. It is a random variation while special cause variations are when one or more factors affected the process in a non-random way. Common causes are part and parcel of the process of production. Variations due to common causes are well expected and accepted. On the other side specific causes are unexpected. Specific causes produce variations which indicate error in the process and limit the capability of the process to deliver quality product. We cannot do much about common cause however special causes need to be identified and corrected for the process to continuously deliver quality product.

Common Cause variations

Common Cause variations are natural issues, noise within the process and random. Though variations are problems but as it is an inherent part of a process, it is expected. Variations due to common cause tells us that the process is healthy. Absence of variations due to common cause indicate some problem in the process.

Common causes examples:

Vibration in industrial processes

Ambient temperature and humidity

Normal wear and tear

Attend PMP Prep Training and clear your PMP Certification Exam?

Click here to enroll yourself in next batch of PMP Certification Prep Training.

Special Causes variations

Special Cause variations are issues developed in a process. These variations were not observed previously and are unusual. They are some kind of defects in the system. Therefore special cause variations must be identified and resolved for the process to deliver quality products. Special cause variation arrives as a surprise as they are not expected and not welcome.

Special causes examples:

Faulty controllers

Machine malfunction

Poor batch of raw material

Power surges

Common cause variations are minor and caused by various environmental factors. They are random and well within accepted limits. Specific cause variations are caused by fault in the process. They may be within accepted limits but are big enough to suppress the randomness of common cause variations to generate a specific pattern. They are often used in control chart for early detection of fault in the process. If points in control chart lose its randomness and show a specific patter (rule of 7), it means process has developed a fault. This may be minor now (still producing product within accepted limits) but if remain unattended may start producing defective product (Out of acceptable limits). This may be major also which may produce product out of acceptable limits. In both the cases, process should be stopped and corrected before continuing.

Control Chart is one of the seven basic quality tools. PMBOK Guide lists these seven basic quality tool in tools and techniques for Project Quality Management. PMP Certification aspirants must understand these quality tools to prepare for PMP Exam. The concept of common cause and specific cause variations will help a PMP Aspirant to understand use of control chart in his/her study for PMP Exam. PMP Certification Training by pmwares covers all such concepts that are important for PMP Exam.